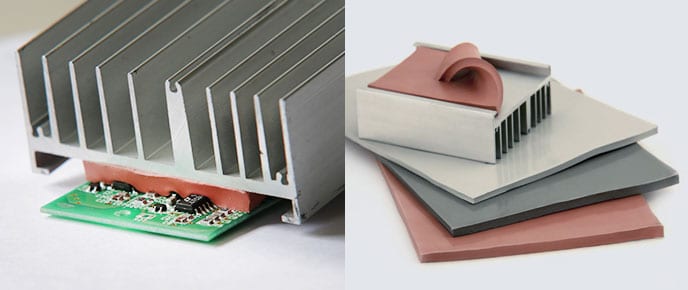

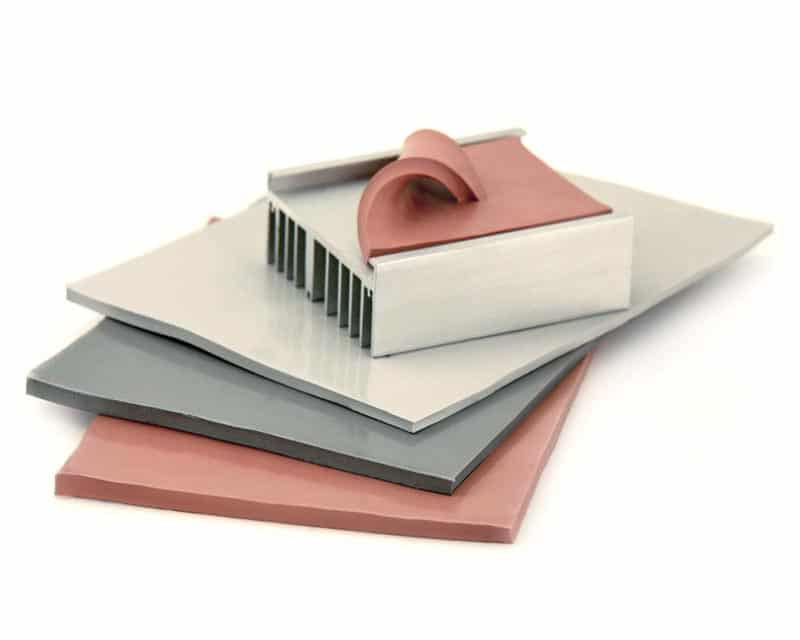

Thermal Gap Fillers are perfect for heat management applications when the distance between the source of heat and dissipating surface is significant, electronic components vary in height, surfaces are very rough and uneven.

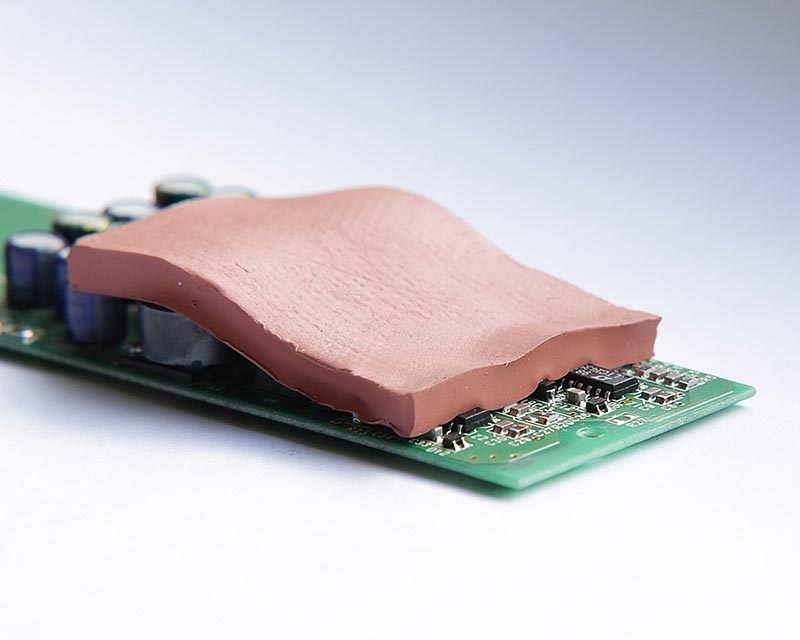

Very soft and conformal, these thermal pad materials are designed to fill in gaps between a heat source and a heat dissipating surface.

Key Features and Standards

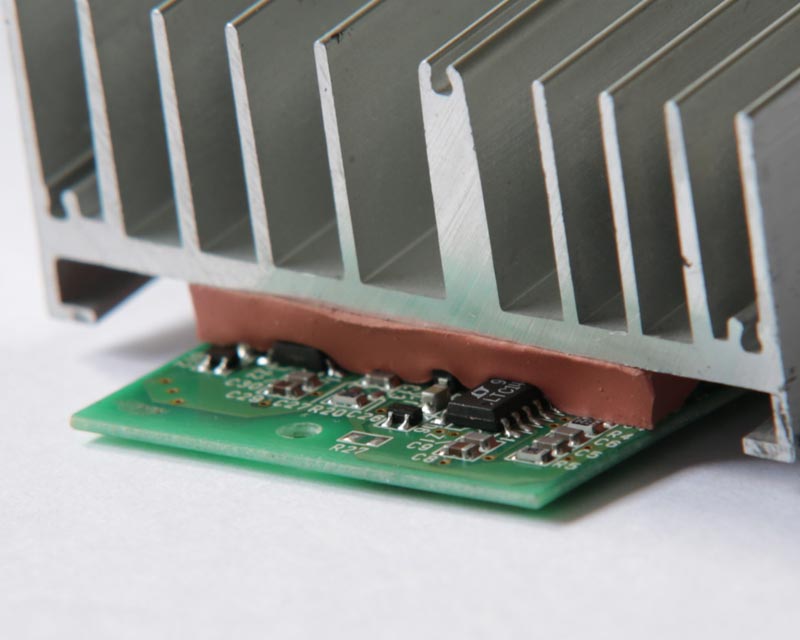

To maximize thermal conductivity, gap filling pads must be compressed to drive the medium into the heat surface texture. For example, the surfaces of a microchip and a heat sink never match perfectly. Even very tiny gaps between these two surfaces would degrade the heat dissipation. The heat generated by the microchip will be better passed to the chassis or heat sink by filling those gaps with the soft thermal gap filler.

Cooler electronic components are more reliable and perform significantly better.

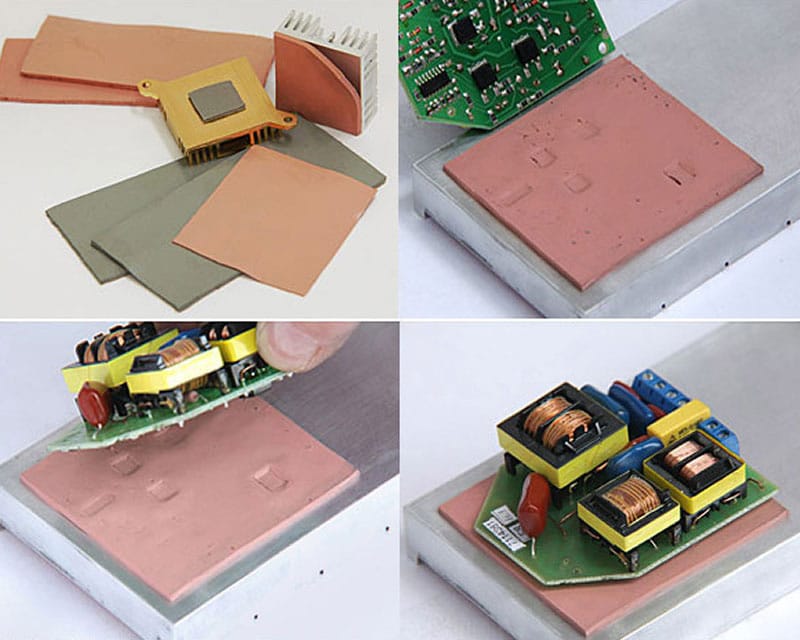

Based on soft and elastic gel-like silicone, EUROLINIA TCEI-2M thermal interface pads are extremely easy to deform (spread) when compressed and tightly conform to all components of the printed circuit board, effectively filling gaps and cavities. These 0.25-6.0 mm thick fillers can serve as gap filling pads between the entire PCB and a heat dissipating component, such chassis of a device or a heat sink, providing high-efficiency volumetric heat dissipation.

Made of the TCEI-2M sheet material products are what we also call the Heat-Conducting Plastic Enveloping Pads, or HCPE™ Pads and HCPE™ 3D-pads are compatible with other well-known material manufacturers for thermal fillers such as Gap Pad®, Gap Filler®, and Softtherm®.

TCEI-2M thermally conductive gap filler materials are manufactured by EUROLINIA as rectangular sheets of two standard sizes:

- 150×110 mm

- 150×220 mm

EUROLINIA TCEI-2M thermal gap fillers provide effective heat dissipation and electrical insulation due to the strong heat-conducting and dielectric properties of ceramic fillers, high thermal relaxation, and conforming to the applied surfaces.

Standard TCEI-2M sheet thickness for ordering is 0.25, 0.50, 0.75, 1.0, 1.5, 2.0, 3.0, 4.0, 5.0 and 6.0 mm. Other non-standard sheet sizes and thickness is available for production upon the customer’s request.

Thermal Gap Fillers are naturally tacky on both sides, which improves handling during assembly.

EUROLINIA Thermal Gap Fillers Line

- TCEI-2M/1 films are produced by filling the silicone base with highly purified Oxide Ceramic micro powders, recrystallized using a special technology at temperatures above 2000 ºС (α-Crystalen™).

- TCEI-2M/2 films are based on Oxide and Nitride ceramic micro powders sintered in a highly purified Nitrogen environment using a unique technology at temperatures above 1200 °C (β-Crystalen™).

- TCEI-2M/3 films are made of Nitride Ceramic micro powders.

- TCEI-2M/1-VN films are made by filling the silicone base with regular spherical shape particles of highly Purified Oxide Ceramic micro powders, which is an extremely high thermal conductivity recrystallized medium.

- TCEI-2M/2-VN films are made by filling the silicone base with regular spherical shape particles of highly Purified Oxide Ceramic micro powders mixed with fractions of Oxide and Nitride Ceramic micro powders sintered in an environment of highly purified Nitrogen using a unique technology at temperatures above 1200 °C (β-Crystalline™).

Production process

The TCEI-2M thermal pad materials are made by the molding method which is a step-by-step contact casting under pressure. As a result, the thermal gap filler appears as a tightly composited sheet of uniform thickness with a smooth and even surface.

High-performance properties of the EUROLININA thermal interface pads are achieved by using the following techniques:

- Use of gel silicone base with maximum elasticity (penetration) and surface tackiness.

- Filling the silicone base with an optimal combination of various heat-conducting ceramic filler micro powders.

- Use of specially developed heat-conducting dielectric α-Cristalen™, β-Cristalen™ micro powder fractions, as well as various fractional composition Nitride Ceramics.

- Producing under pressure a material of the tight structure, homogeneous thickness while leaving zero internal gas cavities.

- Use of thin reinforcing electrical insulating fiberglass base for the sheets of 0.25-1.5mm thickness.

- Sheet surface glossy calibration technology to achieve maximum conformity of the contacting surfaces.

Product Specifications

When operating at high temperatures the TCEI-2M thermal interface pads have the following life span:

- No less than 2,500 hours at 200°С

- No less than 1,500 hours at 250°С

General life expectancy: more than 10 years.

EUROLINIA TCEI-2M Product Specs

| Property | ||||

|---|---|---|---|---|

| Product name | ||||

| TCEI-2М/1 | TCEI-2М/2 | TCEI-2М/3 | ||

| Appearance | Elastic rubber-like homogeneous sheet | |||

| Color | Pink, gray(¹) | Brown, gray(¹) | Gray | |

| Density, g/cm³ | 2,05-2,20 | 1,90-2,10 | 1,80-2,00 | |

| Durometer Shore A | 4-10 / 30-40 | |||

| Thickness, mm | 0,20 – 6,0 | |||

| Stickiness (²), N/m | 100 | |||

| Nominal working compressive stress (MPa), Sheet thickness (mm) | ||||

| 0,20 | 2,2 | |||

| 0,30 | 1,5 | |||

| 0,50 | 0,6 | |||

| Maximum working compressive stress (MPa), Sheet thickness (mm) | ||||

| 0,20 | 7,5 | |||

| 0,30 | 5,5 | |||

| 0,50 | 2,8 | |||

| Maximum compression ratio (elasticity),% | 50 | |||

| Dielectric Strength, KV/mm | ||||

| – D.C. | 25 | 20 | 15 | |

| – A.C. | 18 | 15 | 10 | |

| Volume Resistivity, Ohm•cm | 1014 | 1013 | 1012 | |

| Dielectric Constant at 1,000Hz | 6,5 | |||

| Dielectric loss tangent at 1,000Hz | 0,0045 | |||

| Thermal conductivity, W/(m•К) | 0,80 | 1,10 | 1,40 | |

| Specific thermal resistance, (K•cm²)/W, with a sheet thickness of 0.25 ± 0.02 mm and a compression pressure of 0.69 MPa (100 psi) | 3,20 | 2,50 | 2,10 | |

| (¹) – Any custom color is available according to the customer’s request | ||||

EUROLINIA TCEI-2M-VN Product Specs

| Property | ||

|---|---|---|

| Product name | ||

| TCEI-2М/1-ВН | TCEI-2М/2-ВН | |

| Appearance | Elastic rubber-like homogeneous sheet | |

| Color | pink, gray(¹) | brown, gray(¹) |

| Density, g/cm³ | 2,75-2,85 | 2,60-2,65 |

| Durometer Shore A | 0-5 / 30-35 | |

| Thickness, mm | 0,25 – 6,0 | |

| Stickiness, N/m | 100 | |

| Nominal working compressive stress (MPa), Sheet thickness (mm) | ||

| 0,20 | 1,8 | |

| 0,30 | 1,1 | |

| 0,50 | 0,4 | |

| Maximum working compressive stress (MPa), Sheet thickness (mm) | ||

| 0,20 | 5,0 | |

| 0,30 | 3,5 | |

| 0,50 | 1,8 | |

| Maximum compression ratio (elasticity),% | 50 | |

| Dielectric Strength, KV/mm: | ||

| – D.C. | 25 | |

| – A.C. | 18 | |

| Volume Resistivity, Ohm•cm | 1014 | |

| Dielectric Constant at 1,000Hz | 6,5 | |

| Dielectric loss tangent at 1,000Hz | 0,0045 | |

| Thermal conductivity, W/(m•К) | 2,0 | 2,5 |

| Specific thermal resistance, (K•cm²)/W, with a sheet thickness of 0.25 ± 0.02 mm and a compression pressure of 0.69 MPa (100 psi) | 1,60 | 1,40 |

| (¹) – Any custom color is available according to the customer’s request | ||

Directions for Use

- To use the TCEI-2M, first, you need to draw and cut out the required gap filler pad without removing the protective films from the surface of the sheet.

- Peel off the front protective film and place the filler pad onto one of the heat transfer contact surfaces. Carefully peel off the second protective film and press the other heat transfer surface against the surface of the filler pad.

- Nominal compressive stress (MPa) defines the permissible relative deformation of a sheet in the range from 10% to 50% of its original thickness.

- Maximum compressive stress determines the relative deformation of the material within up to 50% of its original thickness at which there is no loss of elasticity. When the compressive stress is removed, the material is restored to its original thickness and retains its properties.

- The roughness of the contacting surfaces should not exceed Ra = 0.63 μm. Burrs and other defects of the contact surfaces can compromise the integrity of the thermal gap fillers and the electrical insulation. The efficiency of heat removal through a gap filler pad made from a TCEI-2M sheet is determined by:

- The compressive force of the heat source surface and the heat sink;

- Surface flatness and parallelism during assembly;

- Residual air cavities between the gap filler pad and the contacting surface;

- To effectively remove the air cavities, it is recommended to apply the gap filler pad with a glossy surface (sticky side) to the highest quality surface and treat it with a rubber roller.

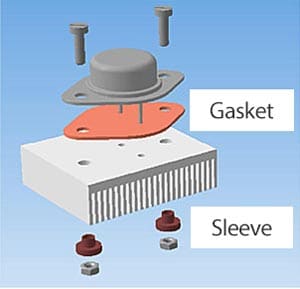

- To insulate semiconductor devices from the heat sink body when fixing with screws, use the M2.5 and M3 insulating sleeves made of heat-resistant polyamide (see Picture 1).

- When using 20 to 1200 cm² large gaskets, it is often difficult to properly prepare the contact surfaces. In such cases, the filler pad thickness and elasticity are not enough to compensate for the defects of the surfaces and their flatness and parallelism during the compression. However, increasing the thickness of the pad leads to an increase in thermal resistance. To avoid this, it is first recommended to apply the heat-conducting paste TCEI-3 onto the contacting surfaces and then install the gap filler pad.

Manufacturer’s Warranty

- The manufacturer guarantees the compliance of the TCEI-2M soft silicone thermal pads with the declared above product technical specifications, subject to proper conditions of transportation, storage, and use.

- Stored in the manufacturer’s package TCEI-2M without tacky layer shelf life: 24 months from the manufacture date.

- Stored in the manufacturer’s package TCEI-2M with tacky layer shelf life: 6 months from the manufacture date.

- Loss of TCEI-2M thermally conductive filler pad tackiness after the shelf life expiration is not considered to be a defective product.

- After the shelf life expiry, the TCEI-2M sheet should be tested before each use for compliance with the technical requirements. Subject to compliance, the TCEI-2M sheet can be used for its intended purpose.

- Quality complaints and claims are accepted when returning the products in the manufacturer’s container with the provision of accompanying documents for the products received from the manufacturer.

Contact Us Today!

To get the product information in the Russian language, please refer to our website nomacon.by